Exploring Our House Park Microelectronics Foundry by Kelly McSweeney

On the microelectronics foundry in Northrop Grumman’s House Park campus, technicians and engineers hover over wafers — the bases that microchips are inbuilt — that allow a variety of missions, from superior satellite tv for pc communications to complicated astrophysics techniques. Within the digital age, microelectronics foundries will not be uncommon, however the one at our House Park website in Redondo Seashore, California, is exclusive: it’s centered solely on creating microchips that may face up to the cruel circumstances of outer house.

Industrial chip producers give attention to effectively producing a whole lot of hundreds of an identical units for client electronics that solely final a couple of years. Whereas which may be tremendous for a mass-produced product, like a cellphone that can be changed in a pair years, it’s not ok for one thing that should work on a satellite tv for pc in house for a decade or extra. Northrop Grumman’s House Park foundry focuses on constructing these customized “golden” chips, as Microelectronics Manufacturing Engineering Part Supervisor Rachael Ferizovic defined. With an ongoing chip scarcity throughout the U.S., our capacity to create these on-site is crucial. Additionally essential is our staff’s capacity to carry out in depth accelerated life testing in-house; that features thermal and electrical stress testing, thermal biking and hermeticity checks.

“We are able to do every thing from design all the way in which to delivering the reliability information,” stated Nancy Lin, a workers engineer who has labored on microelectronics at Northrop Grumman for a decade.

Impossibly Small Electronics

The staff members working on the foundry are lined head-to-toe in specialised clothes comprised of cloth with metallic wire woven all through for grounding, to keep away from electrostatic discharge that might destroy elements. These “bunny fits” are additionally designed to keep away from shedding. Lint and dirt are the enemies of the cleanroom. Even the air is handled with care: A laminar airflow system retains the air transferring in a uniform solution to keep away from particles contaminating the delicate microelectronics. The room is illuminated by yellow lights as a result of blue-toned ultraviolet gentle might harm the photoresist used to type the miniature digital elements, resembling transistors and amplifiers.

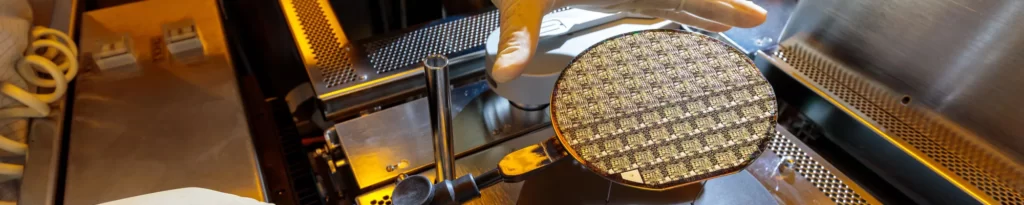

There, they produce 4-inch wafers that include a whole lot of microchips, and people chips are made from even smaller elements. Technicians construct the elements utilizing a course of referred to as photolithography, which is analogous to utilizing a stencil.

“The wafer is what the technicians and engineers are dealing with, and as soon as it’s gone by the buildup of the circuit, the wafer will get diced into particular person chips. Then, technicians use tweezers to get every particular person chip,” defined Rachael.

Nancy and Rachael focus on radiofrequency chips for communication satellites for the Division of Protection. Their present focus is on increased frequencies, which offer the U.S. army with new methods to speak internally.

“I’ve constructed techniques with chiplets which can be about 5 microns aside,” stated Nancy. Chiplets are tiny, modular chips that may be mixed for increased efficiency, and that scale is unfathomably small — 5 microns is about 1/20 the dimensions of a human hair.

Making a Worldwide Impression

At House Park, like all of our websites throughout the U.S., there’s a way that something is feasible. In addition to being famend for his or her work in microelectronics, engineers work on every thing from communications to complicated astrophysics techniques. (It’s the place the James Webb House Telescope was assembled.)

“We’ve actually fostered the artistic tradition at Northrop Grumman,” Nancy stated. “In case you can assume it, we will construct it.”

For instance, the consultants on the House Park foundry developed a brand new know-how referred to as Wafer Stage Packaging that hermetically seals the microchips on the chip stage. This know-how makes manufacturing quicker, cheaper and yields a lighter load on the satellite tv for pc.

For the staff at House Park, like throughout our firm, there’s a deep sense of goal past the every day particulars. The work is about extra than simply wafers and microscopic instruments, and for some its private — together with Rachael, who shared that her brother did two excursions in Afghanistan whereas serving within the U.S. Marine Corps.

“Figuring out that every one our onerous work is about defending our service members makes any challenges and stress value it,” famous Rachael.

Northrop Grumman was chosen in September 2023 to help the “CHIPS and Science Act.” Discover what it’s wish to work at Northrop Grumman and our tradition of innovation and creativity.

Manufacturing & Engineering Journal | The Dwelling of Manufacturing Trade Information