Regardless of having heard the music most likely 50 occasions within the final two years, I found there are notes in David Bowie’s “Starman” that I’d by no means heard till one morning in early November. That’s once I bought to attempt a prototype noise-canceling earbud from xMEMS.

The five-year-old startup focuses on making audio system from microelectromechanical programs (MEMS) silicon-and-piezoelectric chips. Its present designs are beginning to seem in shopper gadgets, they usually have many benefits over at this time’s miniature audio system. These beforehand hidden notes in “Starman” are simply one in all them. However their peak quantity has by no means been sufficient to beat a technical requirement of noise-cancelling earbuds—20 extra decibels within the bass register. A brand new MEMS tech, known as Cypress, varieties audible tones by producing and mixing ultrasound and will give chip-scale audio system sufficient oomph for the job and possibly even lead the tech takeover for different small audio system, like these in automobiles and computer systems.

“Most standard audio system generate sound by actuating and pushing a diaphragm; you’re pushing air to generate sound,” says Mike Householder, vice chairman of selling and enterprise growth at xMEMS. With Cypress, he says, “We’re really going to make use of ultrasonic modulation and demodulation to create strain and generate sound…that is essentially the primary time people are experiencing sound generated differently.”

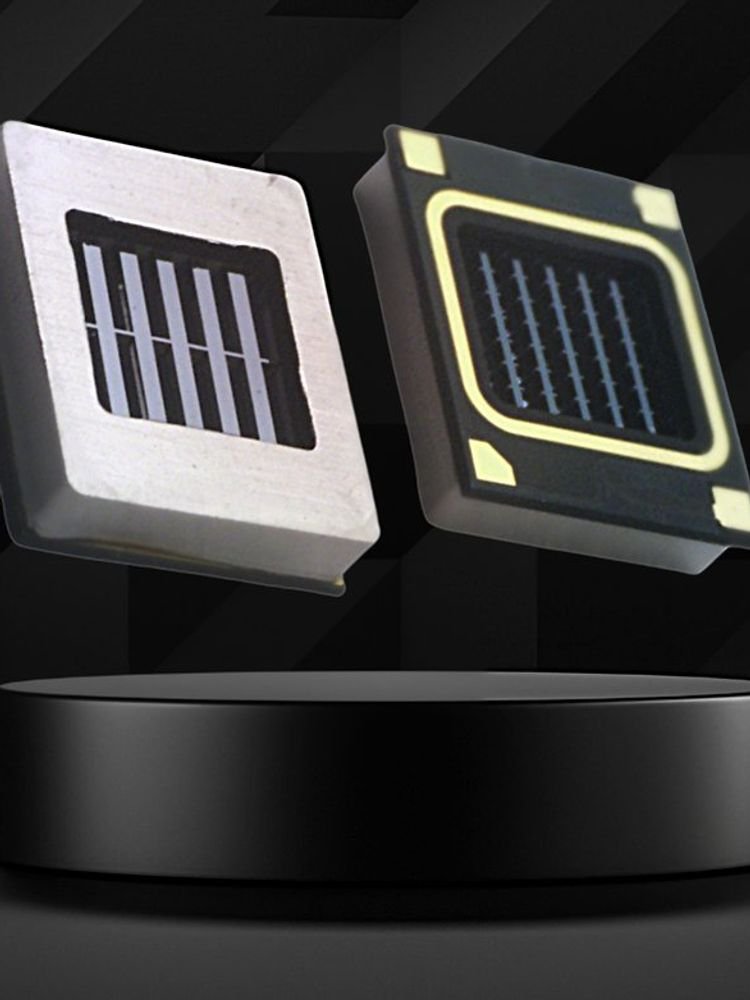

The Cypress MEMS speaker chip is about 9 millimeters diagonally.xMEMS

MEMS chips have already conquered the microphone market, making up nearly all of microphones offered even 5 years in the past, in line with the Yole Group market analysis agency. However audio system demand one thing totally different from MEMS, explains Householder. They must propel a quantity of air, quite than be pushed by it. xMEMS audio system going into merchandise now are chips with a number of silicon flaps coated in piezoelectric materials that vibrate at audible frequencies.

XMEMS has already delivered an a variety of benefits of MEMS know-how. MEMS chips focusing on audible frequencies embrace very low section distortion. That’s the variation within the timing of an acoustic sign in line with its frequency. In an earlier article,Brian Lucey, a mastering engineer who has labored on 9 Grammy-winning albums, advised IEEE Spectrum:

“Section inaccuracy is so ubiquitous that we merely settle for it…. Driver know-how to date has by no means been capable of be this correct. It’s actually not a query of what does it sound like when it’s inaccurate, as a result of that’s simply regular to our ears. It’s extra a query of what does it sound like when it’s this close to completely correct…. Every part is hitting you on the similar time. There’s no time smear in the way in which the sound comes throughout.”

From a producing and engineering standpoint, MEMS is a win, as nicely, argues Householder. For one factor, it’s a much less advanced system, made up of only a single packaged chip and an accompanying IC as an alternative of a posh meeting of coil, magnet, diaphragm, and different components. Coil audio system require labor-intensive manufacturing and testing, partly due to inconsistencies from unit to unit. And MEMS enable for simpler earbud design, as a result of they don’t trigger electromagnetic interference like coil audio system they usually don’t require a selected quantity of air in the back of the earbud to enhance sound high quality.

MEMS Noise-Cancellation Downside

All that’s sufficient for some purposes, however for “true wi-fi stereo” earbuds there’s a catch. When you’ve got a pair, and also you most likely do, you’ll discover a tiny air vent. It’s there for 3 causes, Householder explains. One is to vent uncomfortable strain from between the bud and your ear canal. One other is to cut back an odd impact the place your individual voice will get amplified inside your head. And the third is to facilitate energetic noise cancellation.

The Cypress MEMS speaker chip is loud sufficient to accommodate energetic noise canceling with out a further woofer.xMEMS

Energetic noise cancellation depends on algorithms that assume a comparatively steady seal between the bud and your ear. However actual life doesn’t work that method. The buds shift in atypical use and the seal is just not constant. The vent is supposed to be a a lot bigger leak within the system than any small breaks within the seal, overwhelming the small modifications and permitting the noise-cancellation algorithm to do its work, Householder explains.

“The draw back is whenever you open air to a speaker,” it results low frequencies, he says. “That’s simply the physics of audio system.” In an earbud you’ll sometimes lose about 20 decibels of low frequency, he says. On their very own xMEMS audio system in gadgets at this time can hit 120 dB, and, sure, that’s a fairly unhealthy degree already. However to cancel out the jackhammers and jet engines of the world, you want 140 dB at low frequency.

To make up the distinction with a MEMS system, designers at the moment pair it with a coil speaker that’s used as a woofer. However xMEMS new ultrasound tech can do the entire job by itself, says Householder.

How xMEMS Ultrasound Tech Works

Ultrasound is formed into pulses with an envelope at an audio frequency.xMEMS

In step one, a customized IC modulates an ultrasound provider sign with the audio sign. The result’s an ultrasound sign whose amplitude is the form of the audio sign. This mixed sign drives a pair of cantilevers that flip the sign into ultrasonic strain waves contained in the speaker chamber. A second sign then periodically vents the chamber, producing a collection of strain spikes whose envelope is the audio sign we hear.

The brand new chip is successfully 40 occasions as loud, reaching greater than 140 dB even on the lowest finish of human listening to, 20 hertz. And that’s adequate to do the job of energetic noise cancellation. Simply as necessary, it provides the know-how a path to shopper merchandise that want much more quantity, similar to smartphones and laptops.

Sure early clients are already sampling the prototype Cypress chips, and manufacturing samples are set to ship in June 2024, with mass manufacturing set for late 2024.

From Your Web site Articles

Associated Articles Across the Internet